Stainless Steel Screws-Hebei Gardepot Technology Co., Ltd|Corrosion Resistance&High Strength

Introduction

Stainless steel screws are a critical component in modern manufacturing and construction, offering unmatched durability and reliability. These fasteners are engineered to withstand harsh environments while maintaining structural integrity. For industries ranging from construction to electronics, stainless steel screws provide a secure, long-lasting solution. This article delves into the features, advantages, technical specifications, and applications of stainless steel screws, as well as insights into the company behind this innovative product: Hebei Gardepot Technology Co., Ltd..

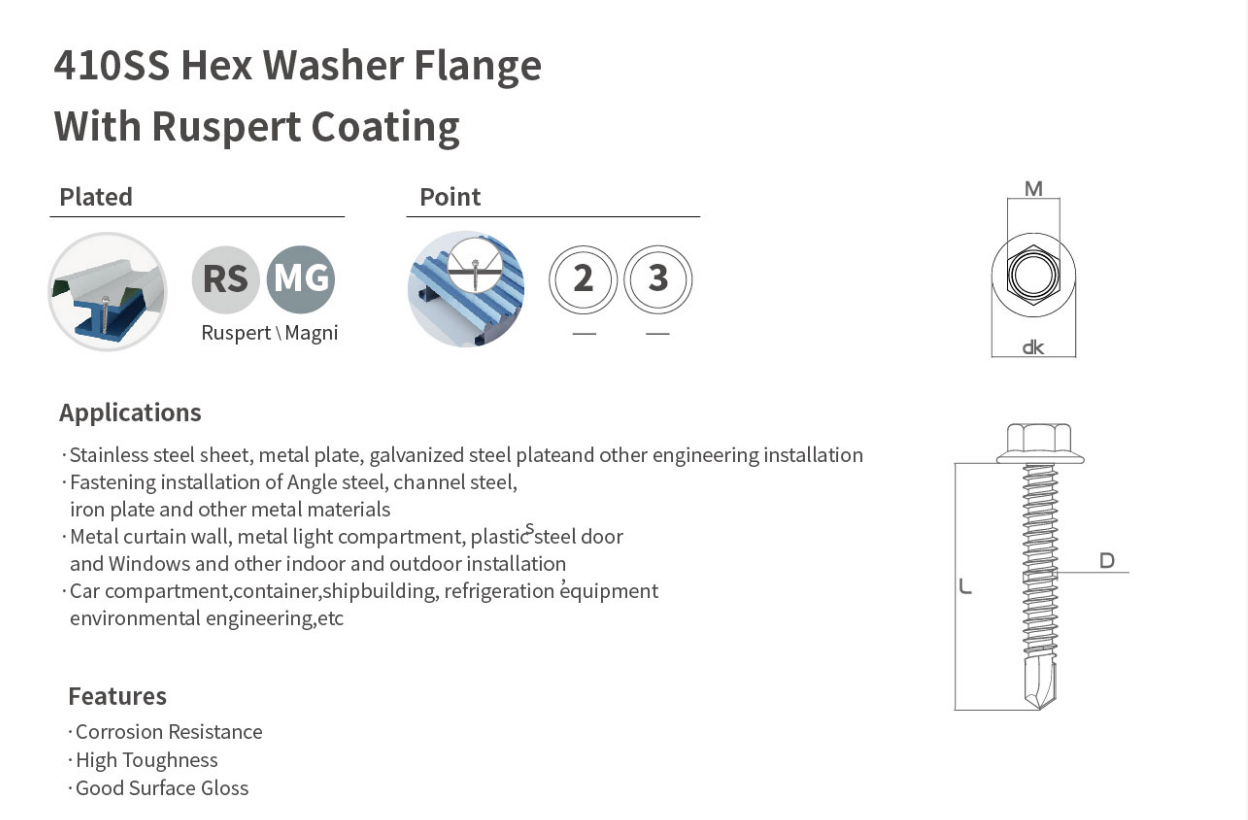

Product Overview

Stainless steel screws are a premium fastening solution designed for strength, durability, and long-lasting performance in various applications. Crafted from high-quality stainless steel, these screws are inherently resistant to rust, corrosion, and wear, making them ideal for both indoor and outdoor environments. Their versatility and reliability make them a preferred choice across industries such as construction, automotive, marine, and electronics, as well as in DIY and home improvement projects.

The product overview highlights their ability to endure harsh conditions while providing a secure and strong hold. Whether used in structural frameworks or delicate electronic components, stainless steel screws ensure consistent performance. Their resistance to environmental factors like humidity and saltwater makes them particularly valuable in marine and coastal applications.

Key Features of Stainless Steel Screws

Stainless steel screws are celebrated for their exceptional properties, which make them a top choice for demanding applications. Below are the standout features that define their performance:

- Corrosion Resistance: The primary advantage of stainless steel screws is their exceptional resistance to corrosion. Stainless steel’s inherent properties prevent rust and degradation, even in high-humidity or saltwater environments, ensuring a long-lasting, reliable fastener. This makes them ideal for marine, coastal, and industrial settings where exposure to moisture is common.

- Superior Strength: These screws are known for their superior strength, offering excellent tensile strength and load-bearing capabilities. They are designed to endure heavy-duty applications, ensuring a secure hold for a wide variety of materials, including wood, metal, concrete, and plastics.

- Versatility: Stainless steel screws are incredibly versatile, suitable for a wide range of uses, from construction and automotive to electronics and marine applications. Their resistance to rust and corrosion makes them ideal for both exterior and interior projects.

- Aesthetic Appeal: With a sleek, clean appearance, stainless steel screws complement modern, high-end designs. They offer a polished, shiny finish, adding aesthetic value to furniture, fixtures, and architectural components.

- Ease of Installation: Available in a range of head types, thread patterns, and sizes, stainless steel screws are easy to install using standard tools. Their precision threading ensures a tight grip, and their durability minimizes the risk of stripping or damaging the screw during installation.

Technical Specifications

Understanding the technical specifications of stainless steel screws is essential for selecting the right product for specific applications. Below is a detailed table outlining the key parameters:

| Parameter | Details |

|---|---|

| Material | High-quality stainless steel (e.g., 304, 316 grades) |

| Corrosion Resistance | Exceptional, suitable for marine and industrial environments |

| Strength | High tensile strength (varies by grade and size) |

| Surface Finish | Polished, shiny, and corrosion-resistant |

| Head Types | Flat, hex, pan, and socket head options |

| Thread Patterns | Coarse, fine, or self-tapping threads |

| Size Variants | Available in 8 x 1, 10 x 1, 12 x 1, and other custom sizes |

| Applications | Construction, automotive, marine, electronics, and DIY projects |

Applications Across Industries

Stainless steel screws are indispensable in a wide array of industries due to their robust performance and adaptability. Here’s a closer look at their key applications:

1. Construction

In construction, stainless steel screws are used to secure materials such as wood, drywall, and metal. Their corrosion resistance ensures they can withstand exposure to outdoor elements in roofing, siding, and framing applications. For example, 10 x 1 stainless steel screws are commonly employed in structural frameworks where durability is critical.

2. Automotive and Marine

In the automotive and marine industries, stainless steel screws are used for securing parts and components exposed to moisture, saltwater, and harsh conditions. Their corrosion resistance ensures reliability and longevity in vehicles and boats. 12 x 1 stainless steel screws are particularly favored for marine applications due to their ability to withstand saltwater exposure.

3. Electronics

These screws are used in electronics to secure components such as circuit boards, devices, and housings. The non-corrosive properties ensure long-term stability and reliability for electronic systems. Their precision threading and durability make them ideal for delicate applications where reliability is paramount.

4. DIY and Home Improvement

Stainless steel screws are popular in DIY projects, including furniture assembly, decking, and cabinetry. Their durable finish ensures a clean, polished look while providing a strong, long-lasting hold. 8 x 1 stainless steel screws are often used in furniture assembly for their balance of strength and ease of installation.

Company Background: Hebei Gardepot Technology Co., Ltd.

Hebei Gardepot Technology Co., Ltd. is a leading manufacturer of high-quality fastening solutions, including stainless steel screws. With a commitment to innovation and excellence, the company has established itself as a trusted name in the industry. Their products are designed to meet the rigorous demands of modern applications, ensuring durability, precision, and reliability.

Hebei Gardepot Technology Co., Ltd. prioritizes quality control and adheres to international standards to deliver products that meet the highest expectations. Their website provides detailed information about their product range, including stainless steel screws, and highlights their dedication to customer satisfaction.

For more information about the company’s mission, values, and product offerings, visit Hebei Gardepot Technology Co., Ltd..

Expert Insights and Industry Standards

According to the National Institute of Standards and Technology (NIST), the development and adoption of high-quality fasteners are critical for ensuring the safety and reliability of structures and systems. NIST’s research on material science and corrosion resistance underscores the importance of using materials like stainless steel in environments where durability is paramount.

As noted in NIST’s Handbook 133, "Materials used in critical applications must meet stringent standards to prevent failure under stress or exposure to harsh conditions." This aligns with the properties of stainless steel screws, which are engineered to meet these exacting requirements.

For further reading on NIST’s role in advancing material standards, visit NIST’s official website.

Conclusion

Stainless steel screws are a vital component in modern engineering and construction, offering unmatched durability, corrosion resistance, and versatility. Whether used in industrial, automotive, marine, or DIY applications, these fasteners provide a reliable solution for demanding environments. Hebei Gardepot Technology Co., Ltd. exemplifies the commitment to quality and innovation that defines the industry.

For more information about stainless steel screws and their applications, explore the product page or contact Hebei Gardepot Technology Co., Ltd. directly. With their expertise and dedication to excellence, they continue to set the standard for high-performance fastening solutions.