Stainless Steel Screws-Hebei Gardepot Technology Co., Ltd|Corrosion Resistance,High Toughness

Stainless steel screws have become a cornerstone in modern manufacturing and construction due to their exceptional durability, resistance to corrosion, and versatility across industries. Stainless Steel Screws are engineered to deliver long-term reliability in both indoor and outdoor environments, making them a preferred choice for professionals and DIY enthusiasts alike. This article explores the key features, technical specifications, applications, and the company behind these high-performance fasteners.

Product Overview

Stainless steel screws are a premium fastening solution designed for strength, durability, and long-lasting performance in various applications. Manufactured from high-quality stainless steel, these screws are highly resistant to rust, corrosion, and wear, making them ideal for use in both indoor and outdoor environments. Stainless Steel Screws are commonly used in industries such as construction, automotive, marine, and electronics, as well as in DIY and home improvement projects. Their ability to withstand harsh conditions while providing a secure and strong hold makes them a reliable choice for a wide range of fastening needs.

Produced by Hebei Gardepot Technology Co., Ltd, these screws are designed to meet the demands of modern engineering. The company specializes in high-performance fasteners and has established a reputation for delivering products that combine quality, innovation, and customer satisfaction. Hebei Gardepot Technology Co., Ltd is committed to providing solutions that enhance efficiency and longevity in industrial and commercial applications.

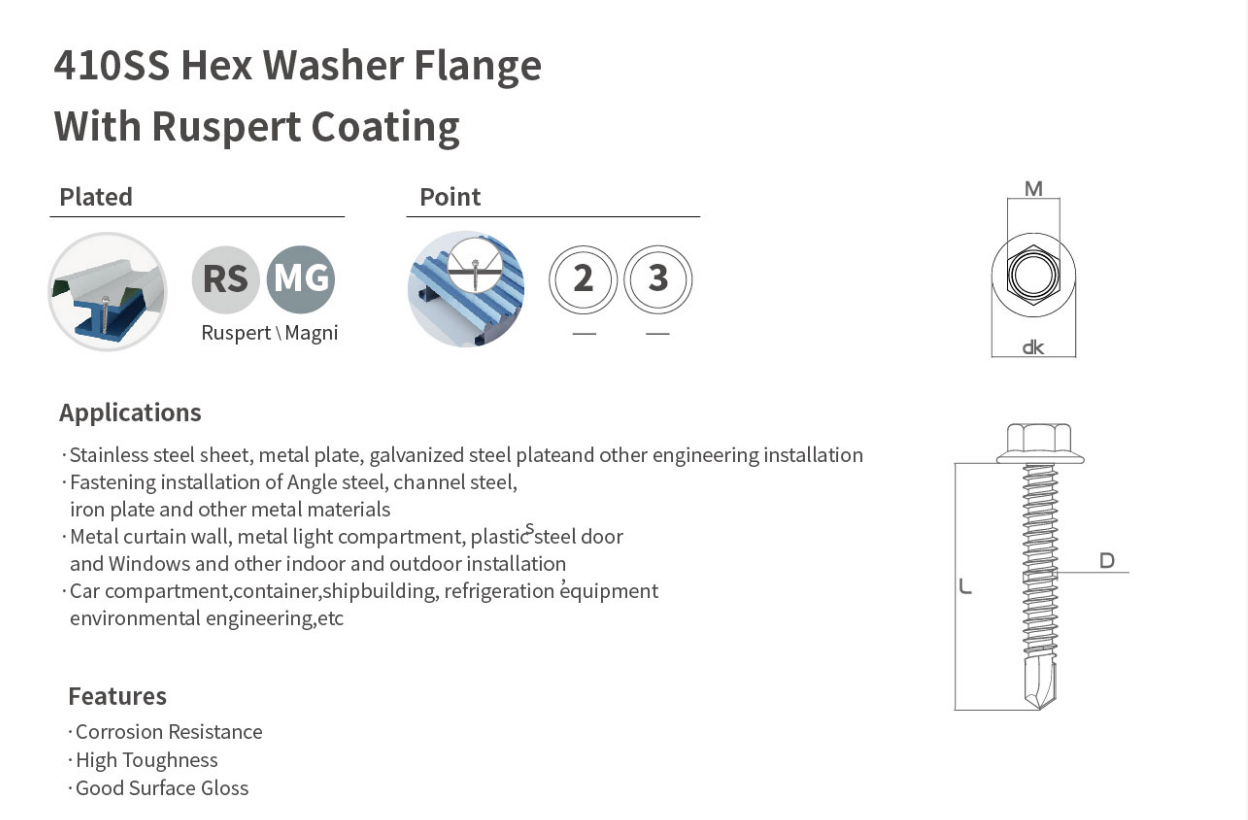

Key Features of Stainless Steel Screws

Stainless steel screws are renowned for their exceptional properties, which make them suitable for a wide range of applications. Here are some of their key features:

- Corrosion Resistance: The inherent properties of stainless steel provide outstanding resistance to rust and degradation, even in high-humidity or saltwater environments. This makes them ideal for use in coastal areas, marine applications, and outdoor construction projects.

- Superior Strength: These screws offer excellent tensile strength and load-bearing capabilities, ensuring a secure hold for materials such as wood, metal, concrete, and plastics. Their robust design makes them suitable for heavy-duty applications.

- Versatility: Stainless steel screws are incredibly versatile, suitable for use in construction, automotive, electronics, and marine applications. Their resistance to rust and corrosion makes them ideal for both exterior and interior projects.

- Aesthetic Appeal: With a sleek, clean appearance and a polished, shiny finish, these screws enhance the visual appeal of furniture, fixtures, and architectural components.

- Easy Installation: Available in a range of head types, thread patterns, and sizes, stainless steel screws are easy to install using standard tools. Their precision threading ensures a tight grip, minimizing the risk of stripping or damaging the screw during installation.

Applications of Stainless Steel Screws

Stainless steel screws are widely used across multiple industries due to their durability and adaptability. Here are some of the key applications:

- Construction: These screws are used for securing materials such as wood, drywall, and metal. Their corrosion resistance ensures they can withstand exposure to outdoor elements in roofing, siding, and framing applications.

- Automotive and Marine: In the automotive and marine industries, stainless steel screws are used for securing parts and components that are exposed to moisture, saltwater, and other harsh conditions. Their corrosion resistance ensures reliability and longevity in vehicles and boats.

- Electronics: These screws are used in electronics to secure components such as circuit boards, devices, and housings. The non-corrosive properties ensure long-term stability and reliability for electronic systems.

- DIY Projects: Stainless steel screws are commonly used in DIY projects, including furniture assembly, decking, and cabinetry. Their durable finish ensures a clean, polished look while providing a strong, long-lasting hold.

Technical Specifications

The following table provides a detailed overview of the technical specifications of stainless steel screws:

| Parameter | Details |

|---|---|

| Material | High-quality stainless steel (e.g., 304, 316) |

| Corrosion Resistance | Exceptional resistance to rust, corrosion, and wear |

| Tensile Strength | High tensile strength for heavy-duty applications |

| Surface Finish | Polished, shiny finish for aesthetic appeal |

| Head Types | Hex, flat, pan, and other standard head types |

| Thread Patterns | Coarse, fine, and self-tapping threads |

| Size Range | Available in various sizes, including 1 x 1 stainless steel screws, 8 x 1 stainless steel screws, 10 x 1 stainless steel screws, and 12 x 1 stainless steel screws |

Company Background: Hebei Gardepot Technology Co., Ltd

Hebei Gardepot Technology Co., Ltd is a leading manufacturer of high-quality fasteners, specializing in stainless steel screws and other precision-engineered components. The company is committed to delivering products that meet the highest standards of quality, durability, and performance. With a focus on innovation and customer satisfaction, Hebei Gardepot Technology Co., Ltd serves a global clientele, providing solutions for industries ranging from construction and automotive to electronics and marine applications.

Hebei Gardepot Technology Co., Ltd is known for its rigorous quality control processes, ensuring that every product meets industry standards and customer expectations. The company's dedication to excellence is reflected in its product portfolio, which includes a wide range of stainless steel screws designed for diverse applications. By combining advanced manufacturing techniques with a customer-centric approach, Hebei Gardepot Technology Co., Ltd continues to set benchmarks in the fastener industry.

Why Choose Stainless Steel Screws?

Stainless steel screws offer several advantages that make them a preferred choice for various applications:

- Longevity: Their resistance to corrosion and wear ensures a long service life, reducing the need for frequent replacements.

- Reliability: These screws provide a secure and strong hold, even in challenging environments.

- Cost-Effectiveness: While stainless steel screws may have a higher initial cost, their durability and low maintenance requirements make them a cost-effective solution in the long run.

- Environmental Friendliness: Stainless steel is a sustainable material that can be recycled, making it an eco-friendly choice.

Conclusion

Stainless steel screws are a critical component in modern engineering and construction, offering a combination of strength, durability, and versatility. Their exceptional resistance to corrosion, high tensile strength, and aesthetic appeal make them suitable for a wide range of applications. Whether you are working on a construction project, automotive repair, or electronics assembly, stainless steel screws provide a reliable and long-lasting solution.

For more information about Stainless Steel Screws and the products offered by Hebei Gardepot Technology Co., Ltd, visit their official website. With a commitment to quality and innovation, the company continues to deliver fastening solutions that meet the evolving needs of industries worldwide.

References

1. National Institute of Standards and Technology (NIST) - While the specific page could not be accessed, NIST provides industry standards and guidelines for materials and manufacturing processes. https://www.nist.gov/